18 Years Factory Automatic Filling Production Line - YB-320 Shaped Bag Packing Machine – Cmore

18 Years Factory Automatic Filling Production Line - YB-320 Shaped Bag Packing Machine – Cmore Detail:

|

Product model |

YB 320 |

|

Production capacity (bag / minute) |

40-120(bag / minute) |

|

Measuring range (ML) |

1-45ml/(1-30ml)*2/(1-15ml)*3/(1-10ml)*4 |

|

Measurement method |

Piston pump / measuring cup / screw |

|

Control system |

Huichuan PLC |

|

Bag making size (mm) |

Length (L) 40-180, Width (W) 40-160 |

|

Total power (Watts) |

3000W |

|

Supply voltage |

220V/50-60Hz;380V/50HZ |

|

Packing material |

Paper / polyethylene, polyester / aluminum foil / polyethylene, nylon / polyethylene, tea filter paper, etc. |

|

Net weight (kg) |

6000kg |

|

Overall dimension |

1460x1600x1800mm(LxWxH) |

|

Machine material |

Material of main parts: stainless steel 304 |

This packaging machine can automatically complete the functions of automatic quantitative measurement, automatic filling, automatic bag making, cutting and tearing, sealing, cutting and other functions of products; The printing cursor can be automatically tracked and positioned, and a complete logo pattern can be obtained when packaging packaging materials with color codes; PLC control can easily set and adjust packaging parameters on the touch screen control panel. Visually display production information, and have the functions of fault self-alarm, shutdown and self-diagnosis, safe and simple to use and easy to maintain; PID digital temperature control, sealing temperature deviation is about 1 degree Celsius. (Any bag type can be customized according to the shape of the customer) It is an ideal bag packaging equipment for food, medicine, cosmetics and other enterprises, R&D institutions, and type selection to replace manual packaging and reduce labor intensity.

1. It is suitable for the measurement and packaging of granules, powders, liquids, sauces and other items in various industries.

2. It can automatically complete bag making, measuring, cutting, sealing, slitting, counting, and can be configured to print batch numbers according to customer requirements.

3. Touch screen operation, PLC control, servo motor control bag length, stable performance, convenient adjustment and accurate detection. Intelligent temperature controller, PID adjustment, to ensure that the temperature error range is controlled within 1 ℃.

4. Packaging material: PE composite film, such as: pure aluminum, aluminized, nylon, etc.

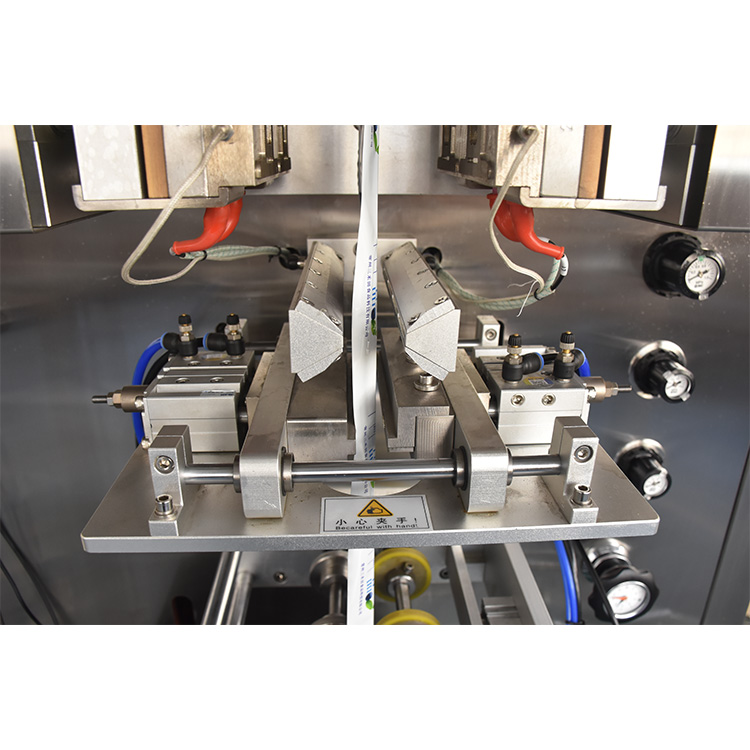

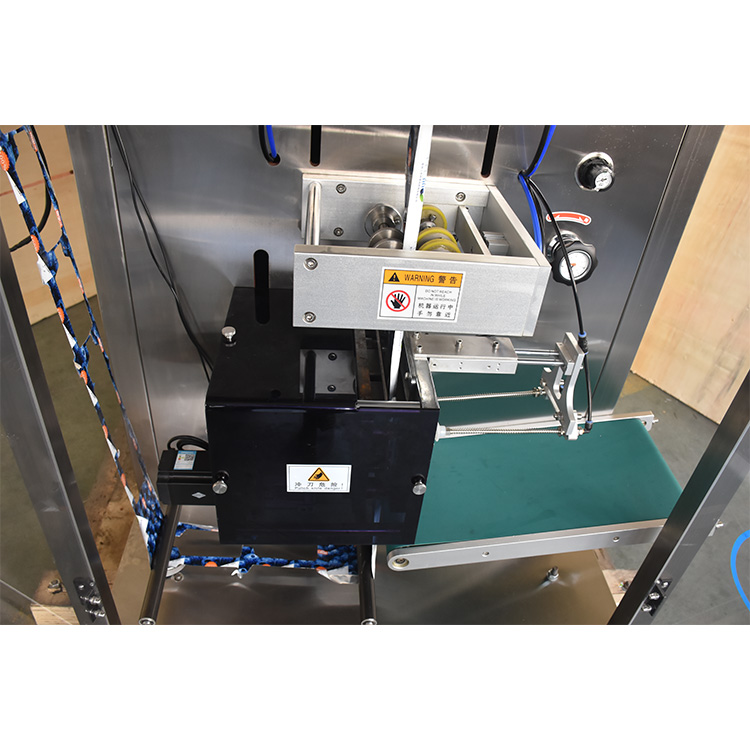

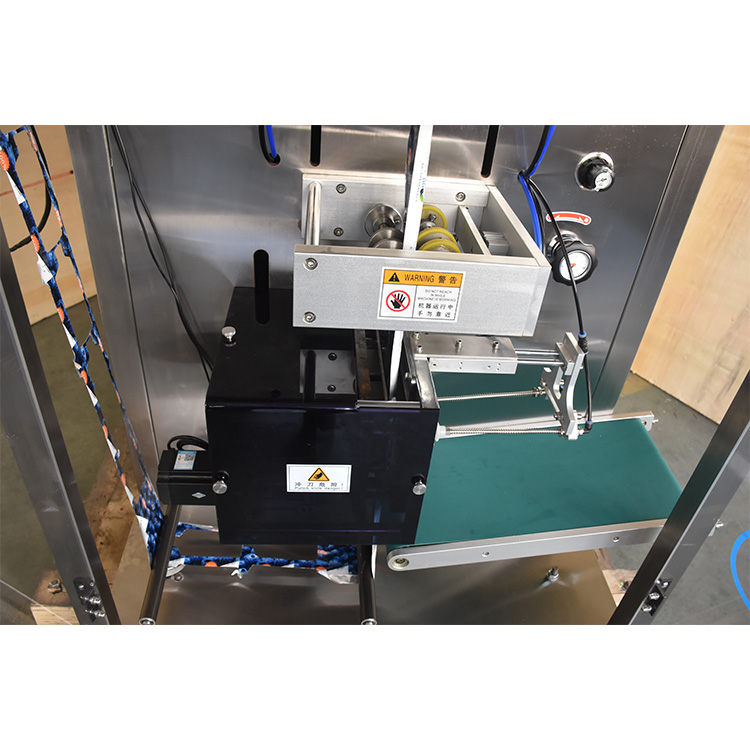

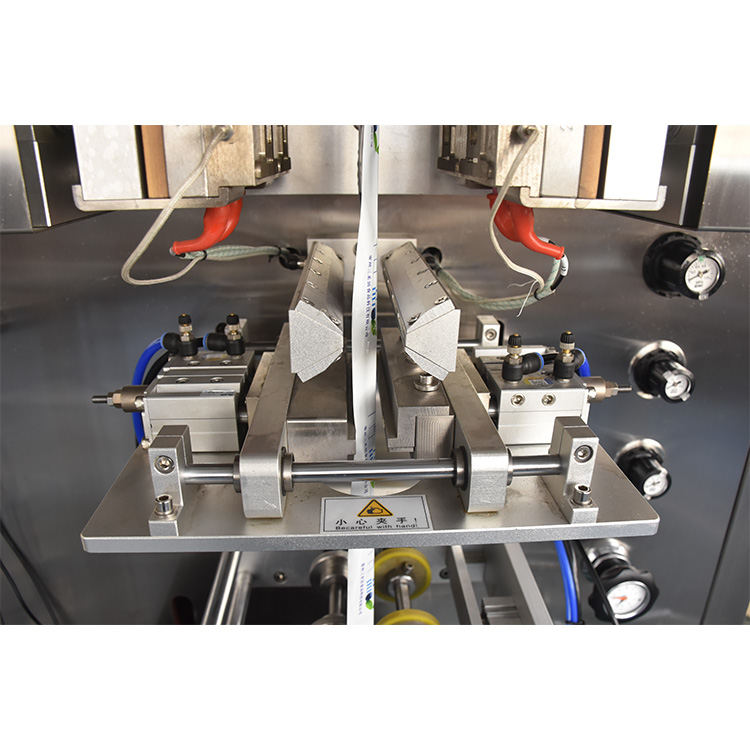

Product detail pictures:

Related Product Guide:

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for 18 Years Factory Automatic Filling Production Line - YB-320 Shaped Bag Packing Machine – Cmore, The product will supply to all over the world, such as: Kyrgyzstan, Lithuania, Albania, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality solutions. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our items and services, please do not hesitate to contact us!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!