Leading Manufacturer for China Plastic Ampoule Filling And Sealing Machine - DGS Series Automatic Plastic Ampoule Forming Filling Sealing Machine – Cmore

Leading Manufacturer for China Plastic Ampoule Filling And Sealing Machine - DGS Series Automatic Plastic Ampoule Forming Filling Sealing Machine – Cmore Detail:

|

Model |

DGS-118 |

DGS-240 |

|

Max Forming Depth |

12mm |

12mm |

|

Cutting Frequency |

0-25 times/min |

|

|

Packing Material |

PVC/PE/PET(0.2-0.4)×120mm |

PVC/PE/PET(0.2-0.4)×240mm |

|

Packing Roll |

Two rolls |

One roll |

|

Filling Volume |

1-50ml |

1-100ml |

|

Filling Head |

5 heads |

|

|

Total Power |

7kw |

|

|

Voltage |

220v-380v/50Hz |

|

|

Weight |

900Kg |

1000Kg |

|

Outer Size(L*W*H) |

2300×850×1500(mm) |

3380×950×1800(mm) |

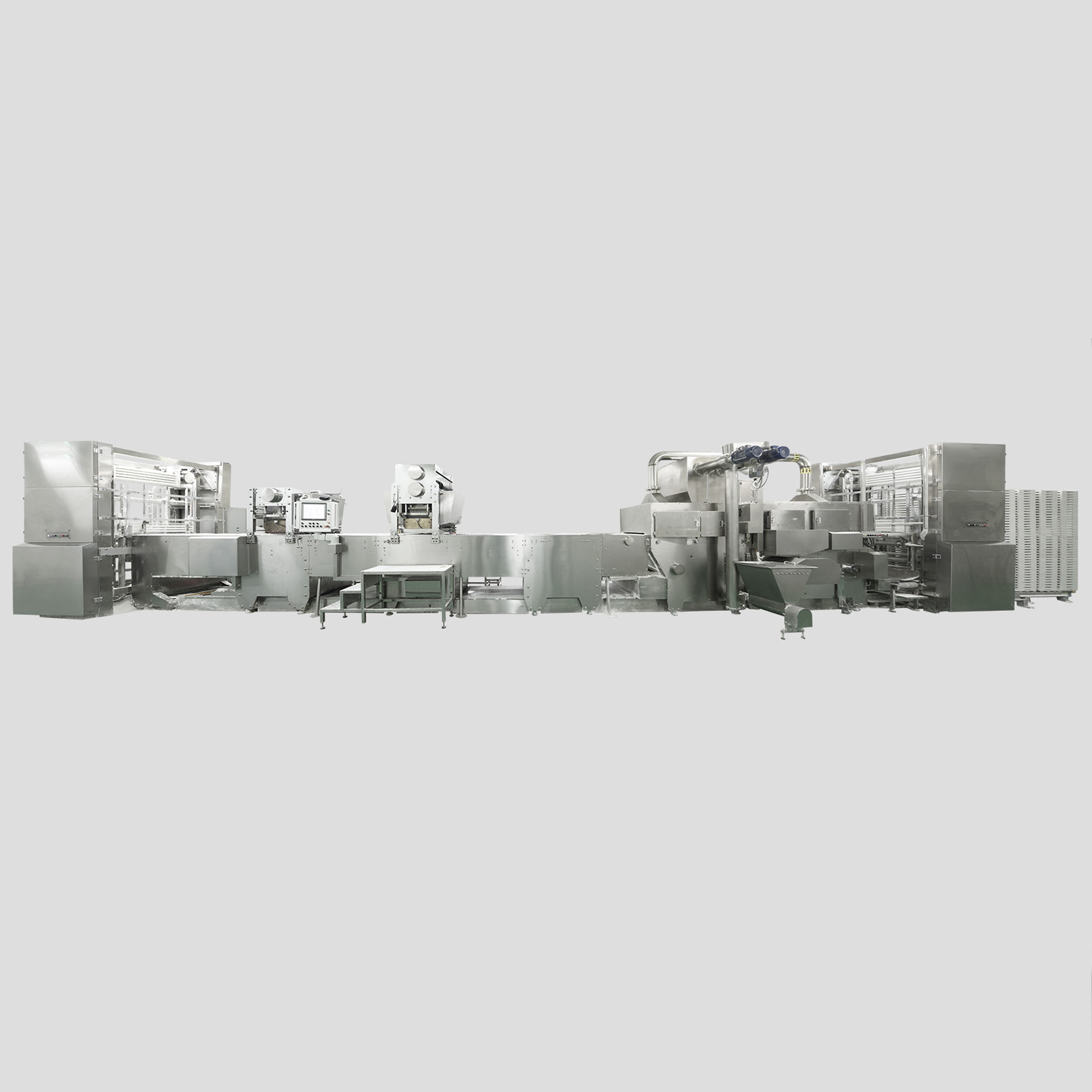

DGS-240 automatic oral liquid plastic bottle forming and filling machine includes a frame, a feeding device and a control system.It has a compact structure, which makes it automatic operation, low manufacturing cost and reliability production efficiency.This machine is suitable for the unit dose of medicine, drinks, dairy products, health products, food, cosmetics, perfume, agricultural medicine, fruit purees, etc.It can finish the following working process including the following:Packing film unwinding–folding–bottle/ampoule forming–product filling–sealing–final product output. We can also add the extra printing and letter or logo engraving function on the machine.

1. High speed and high precision high-end motion controller.

2. Stepless frequency control of motor speed control.

3. Servo motor control tensile membrane device.

4. Automatic discharge volume, a roll of film cutting, can be folded in half.

5. There are positive and negative photoelectric pattern of version of the function. Products elegant, meet high standards of packaging requirements.

6. Using electronic peristaltic pump device. And mechanical pump piston pump control. Filling accuracy is correct.

7. Filling does not drip, no bubble, no overflow.

8. At the bottom of the bottle is flat, could stand.

9. Automatic stop when each door opening.

Product detail pictures:

Related Product Guide:

Gaining client pleasure is our company's aim without end. We are going to make excellent efforts to create new and top-quality goods, meet your special requirements and provide you with pre-sale, on-sale and after-sale companies for Leading Manufacturer for China Plastic Ampoule Filling And Sealing Machine - DGS Series Automatic Plastic Ampoule Forming Filling Sealing Machine – Cmore, The product will supply to all over the world, such as: United Arab emirates, Algeria, Anguilla, Till now, the items list has been updated regularly and attracted clients from around the globe. Comprehensive facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are likely to help you get thorough acknowledge about our goods and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.