Manufacturer of Yoghurt Filling Machine - The Leading Solution For The Fully Automatic Filling And Capping Line (5L-25L) – Cmore

Manufacturer of Yoghurt Filling Machine - The Leading Solution For The Fully Automatic Filling And Capping Line (5L-25L) – Cmore Detail:

| Technical Parameter | |||||

| Head | Capacity (bottle/h) | Compatible Capacity (L) | Total Power (KW) | Total Size (L*W*H) mm | Voltage (V) |

| 4 | 600-800 | 5-25 | About3-4 | 8000x1500x2100 | 380V |

| 6 | 800-1000 | 10000x1500x2100 | |||

| 8 | 1100-1300 | About4-5 | 12000x1500x2100 | ||

| 10 | 1300-1500 | 14000x1500x2100 | |||

| 12 | 1500-1800 | About5-7 | 16000x1500x2100 | ||

Note: The above quantitative error:±0.3-0.5% ml. The above output refers to 5L. The nature of the filling medium is close to that of water, and there is a±10% fluctuation in the speed of different materials.

1.2‰ high- precision Roots flowmeter with high-precision pulse encoder for quantification. Filling accuracy and reliability;

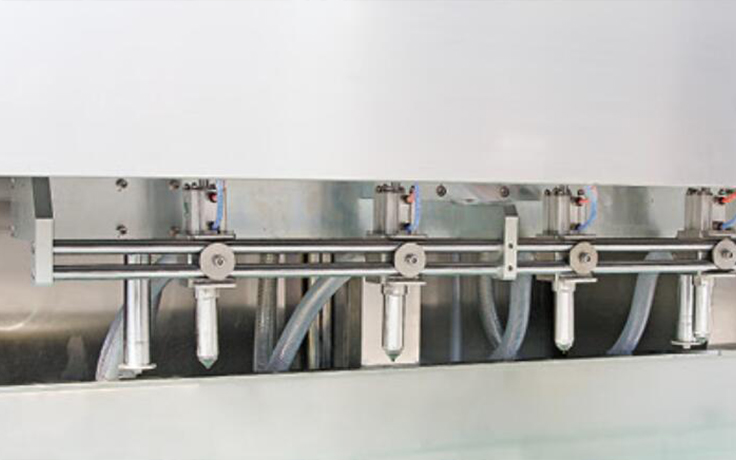

1. The filling head is equipped with an independent vacuum sucking device, and the filling nozzle is uniformly recovered;without dripping, double-speed filling, more stable and no foaming, and more accurate filling.

2. Fast and slow two-speed filling, no bubbling during filling and no spillage of materials;

3. The equipment is compatible with a variety of bottle types and can be used for multiple purposes. Cost- effective equipment.

5. The equipment is simple to operate, complete safety protection measures, and fully protect the safety of users.

6. Food grade stainless steel conveying pipe is safe and sanitary without plasticizer ingredients.

7. It adopts self-configured 2.5kw, 30t/h high-power pipeline pump, automatic suction, and the feeding end is equipped with a bag filter. The whole machine can be used for 10000 hours without consumables.

8. The electrical accessories are all first-line brands such as Germany’s Siemens and France’s Schneider to ensure stable operation and durability of the equipment.

Product detail pictures:

Related Product Guide:

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Manufacturer of Yoghurt Filling Machine - The Leading Solution For The Fully Automatic Filling And Capping Line (5L-25L) – Cmore, The product will supply to all over the world, such as: Bolivia, Burundi, Chile, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant experienced knowledge, to develop advanced production equipment and production process , to create the first-call quality goods, reasonable price , high quality of service , quick delivery , to present you create new value .

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.