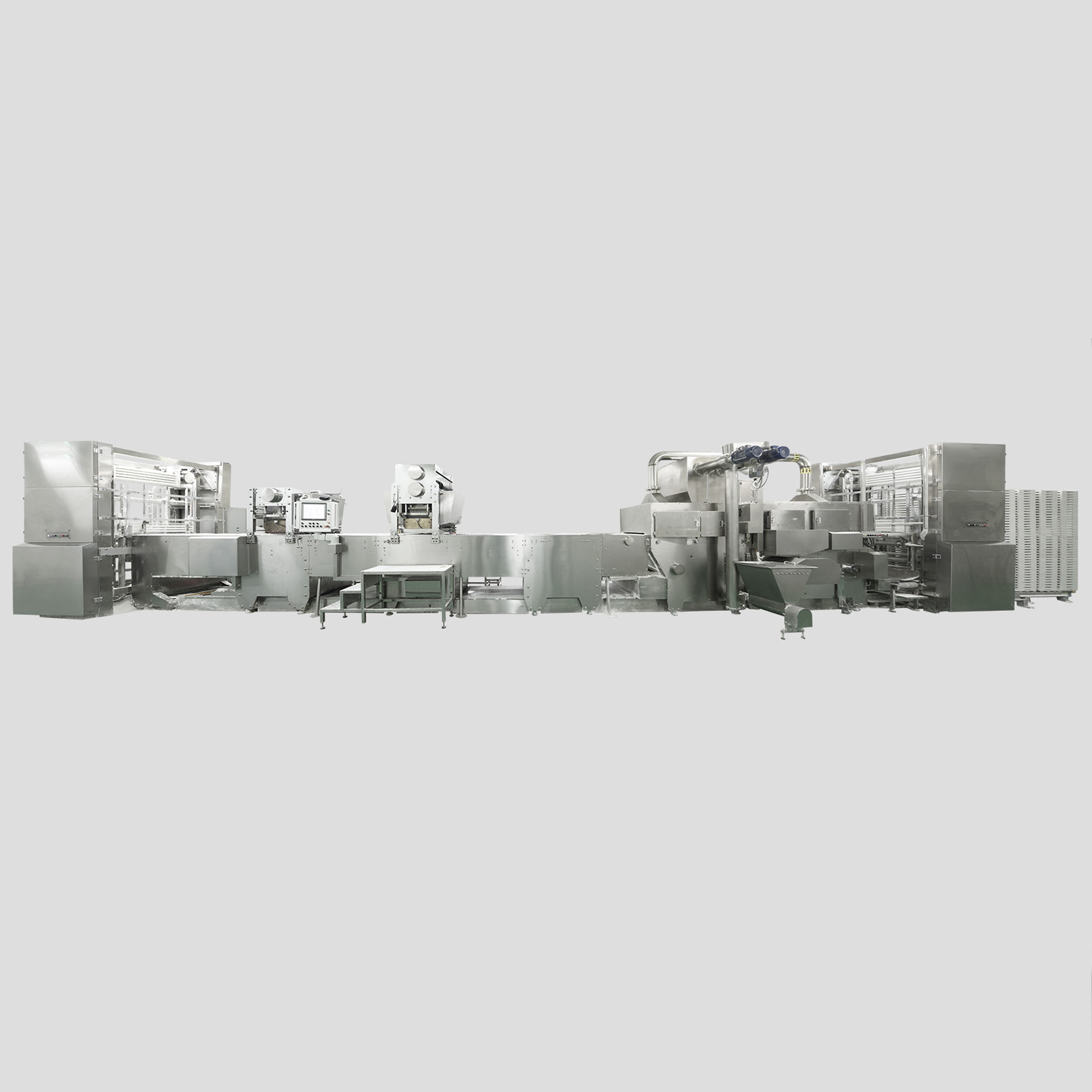

Factory wholesale Sachet Water Making Machine - ARFS-1A Rotary Cup Filling Sealing Machine – Cmore

Factory wholesale Sachet Water Making Machine - ARFS-1A Rotary Cup Filling Sealing Machine – Cmore Detail:

| Model | ARFS-1A |

| Capacity | 800-1000cups/hour |

| Voltage | 1P 220v50hz or customize |

| Total power | 1.3kw |

| Filling volume | 30-300ml,50-500ml,100-1000ml can be choose |

| Filling error | ±1% |

| Air pressure | 0.6-0.8Mpa |

| Air consumption | ≤0.3m3/min |

| Weight | 450kg |

| Size | 900×1200×1700mm |

Whole machine is made by stainless steel 304 and anodizing aluminum, ensures it can run in bad food factory environment which has damp, steam, oil, acidity and salt etc. Its body can accept the water rinsing clean.

Using high quality imported electrical parts and pneumatic parts which ensures the stable running in long time, reduces the stop and maintenance time.

● Rotary plate driven system: servo motor with planetary gear reducer for the rotary table stepping running, it can rotate very fast but avoid material splashing because servo motor can start and stop smoothly, and also keep the positioning accuracy.

● Empty cup falling function: it adopts spiral separating and pressing technology which can avoid the cup damaging and deforming, it has vacuum sucker which can guide the cup to enter into mold accuracy.

● Empty cup detecting function: it adopts photoelectric sensor or optical fiber sensor to detect the mold have or haven’t empty cup, it can avoid the mistake filling and sealing if the mold without the cup, reduce the product waste and machine cleaning.

● Quantitative filling function: it uses piston filling and cup lifting function, no splash and leakage, the filling system tool free disassemble design and has CIP clean function.

● Aluminum foil film placing function: it is made up by 180 rotate vacuum sucker and film magazine, it can place the film on the mold fast and accuracy.

● Sealing function: it is made up by heating seal mold and air cylinder pressing system, the sealing temperature can 0-300 degree adjustment, based on Omron PID controller and solid-state relay, temperature difference less than +/- 1 degree.

● Discharge system: it is made up by cup lifting and pulling system, faster and stable.

● Automation control system: it is made up by PLC, Touch screen, servo system, sensor, magnetic valve, relays etc.

● Pneumatic system: it is made up by valve, air filter, meter, pressing sensor, magnetic valve, air cylinders, silencer etc.

● Safety guards: it is optional function, it is made up by PC plates and stainless steel, has safety switches which protect the operator.

Product detail pictures:

Related Product Guide:

Our solutions are widely regarded and trustworthy by consumers and may meet continually modifying financial and social requirements for Factory wholesale Sachet Water Making Machine - ARFS-1A Rotary Cup Filling Sealing Machine – Cmore, The product will supply to all over the world, such as: Sri Lanka, Jeddah, Morocco, we're now looking forward to even greater cooperation with overseas customers based on mutual benefits. We are going to work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.